Our products

We not only understand technology, we also understand industries and their specific needs. Through close dialogue with our customers, we deliver solutions that have always proven themselves in practice.

Industrial sawing systems

Anthon cut-to-size lines claim to be able to offer a flexible solution for every requirement. Whether single-axis saw, semi-automatic or fully automatic angular system – the customer’s special requirements are included in the planning right from the start.

Portal saws, multi-blade saws and special saws also complement the range of Anthon cut-to-size lines.

Handling / Periphery

The larger the production line or plant, the more decisive smooth processes and a constant high throughput are for economic efficiency – because every millisecond costs valuable time and margin.

That’s why we at Anthon offer you individual solutions for your plant peripherals that work “hand in hand” with our machines.

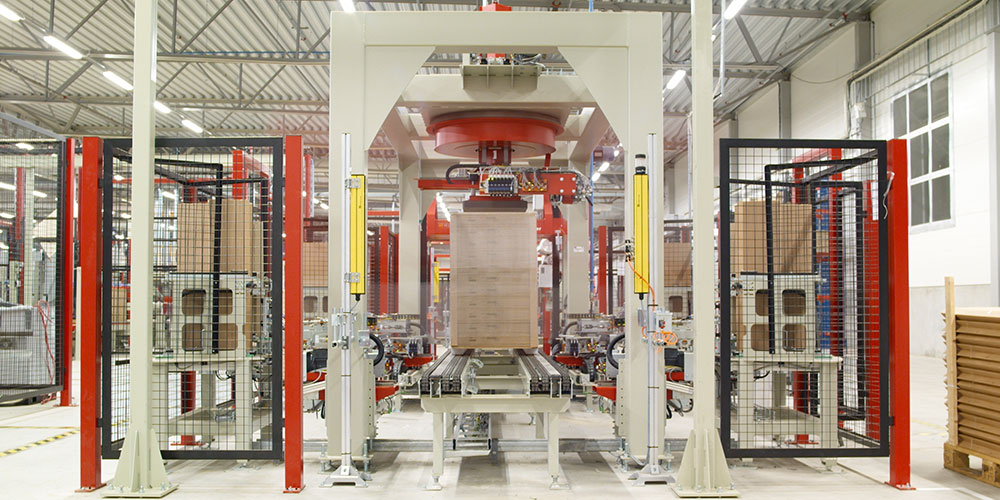

Fully automated packing lines

We realise fully automated packing systems. With robots, wrappers, strapping machines and other units designed for individual packaging purposes with large or small series production. Combined with various transport devices, this creates complete packaging systems which are the continuation of the proven Anthon panel dividing systems.

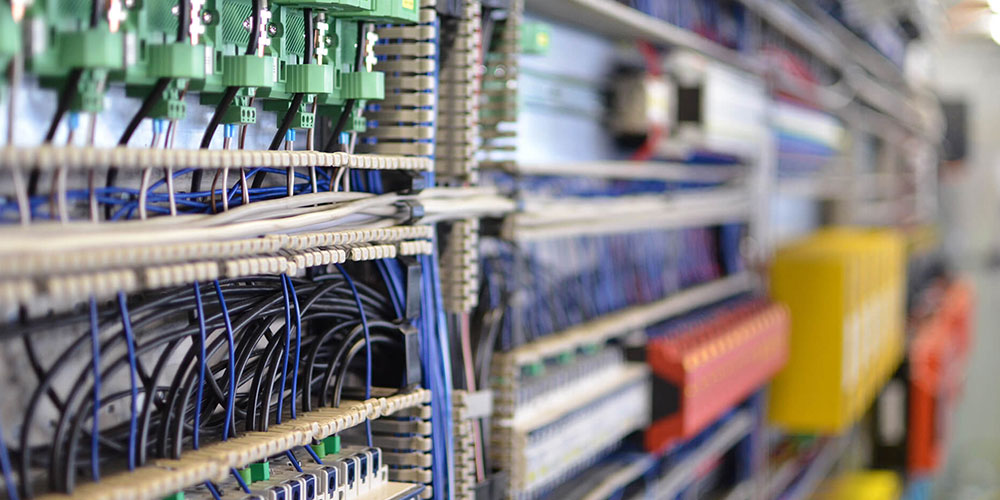

Software / Control IT

The digital age is characterised by modern production processes. Only intelligent software and management and control IT can manage the challenges posed by advancing technologisation, mass production and international markets. Achieving the best possible results under time and cost pressure is the motto – online production the goal.

Anthon on the move

Fairs & Events

Where the industry comes together, we are also there and look forward to interesting encounters: