Manufacturing at a high level

Batch size 1

Industry 4.0 and batch size 1 production are buzzwords that are used constantly and in many places today.

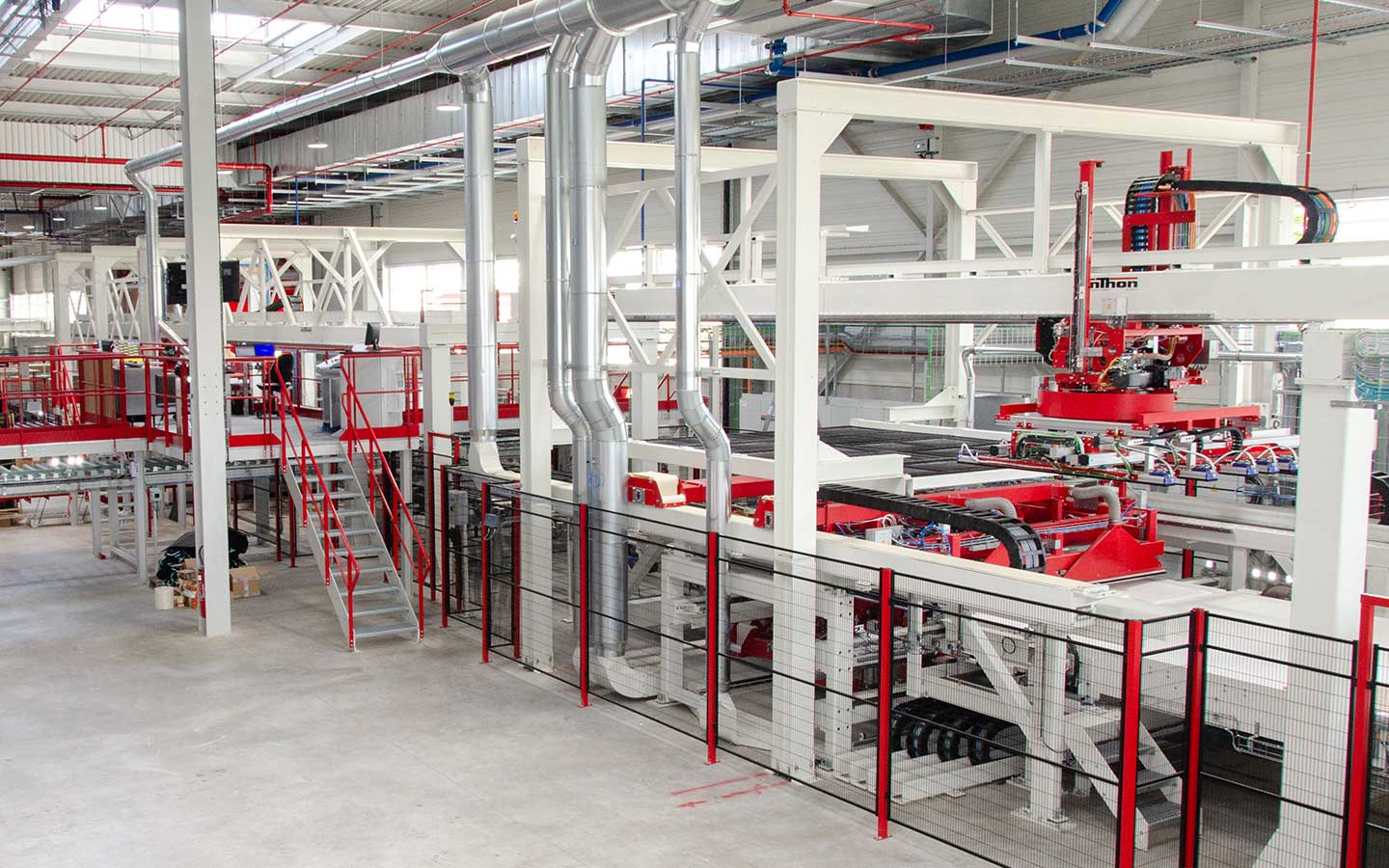

With a combination of longitudinal and multi-blade throughfeed saws with several units, up to 20 parts per minute can be produced, depending on the system variance. Each part can be different – for kitchens, offices, bathrooms and much more. Automatic cutting dimension setting with transfer of the data set from the work preparation and parts handling with the help of vacuum traverses enable fully automatic batch size 1 production.

The MES takes over the cutting patterns from the postprocessor in order to be able to track each panel through the complete system and the entire production process. Synchronisation is monitored at defined measuring points.

The material is moved over table supports by means of a pusher that operates from above. When the saw units are adjusted, the upper pressures also move to the new positions. The adjustment of the saw units and the adjustment of the upper pressure is done by servo motors. This ensures that the saw unit and the upper pressure are always on top of each other, thus achieving the highest cutting accuracy. The positioning to the new cutting position is carried out time-neutrally during the return travel of the top pressure, which transports the material over the saw units.

| Areas of application |

|---|

| Product solutions for the entire furniture industry |

| Product solutions as angular systems, throughfeed saws or combinations of both |

| Product solutions for outputs from 3 to 20 parts per minute |

| Product solutions including feeding, sorting and picking |