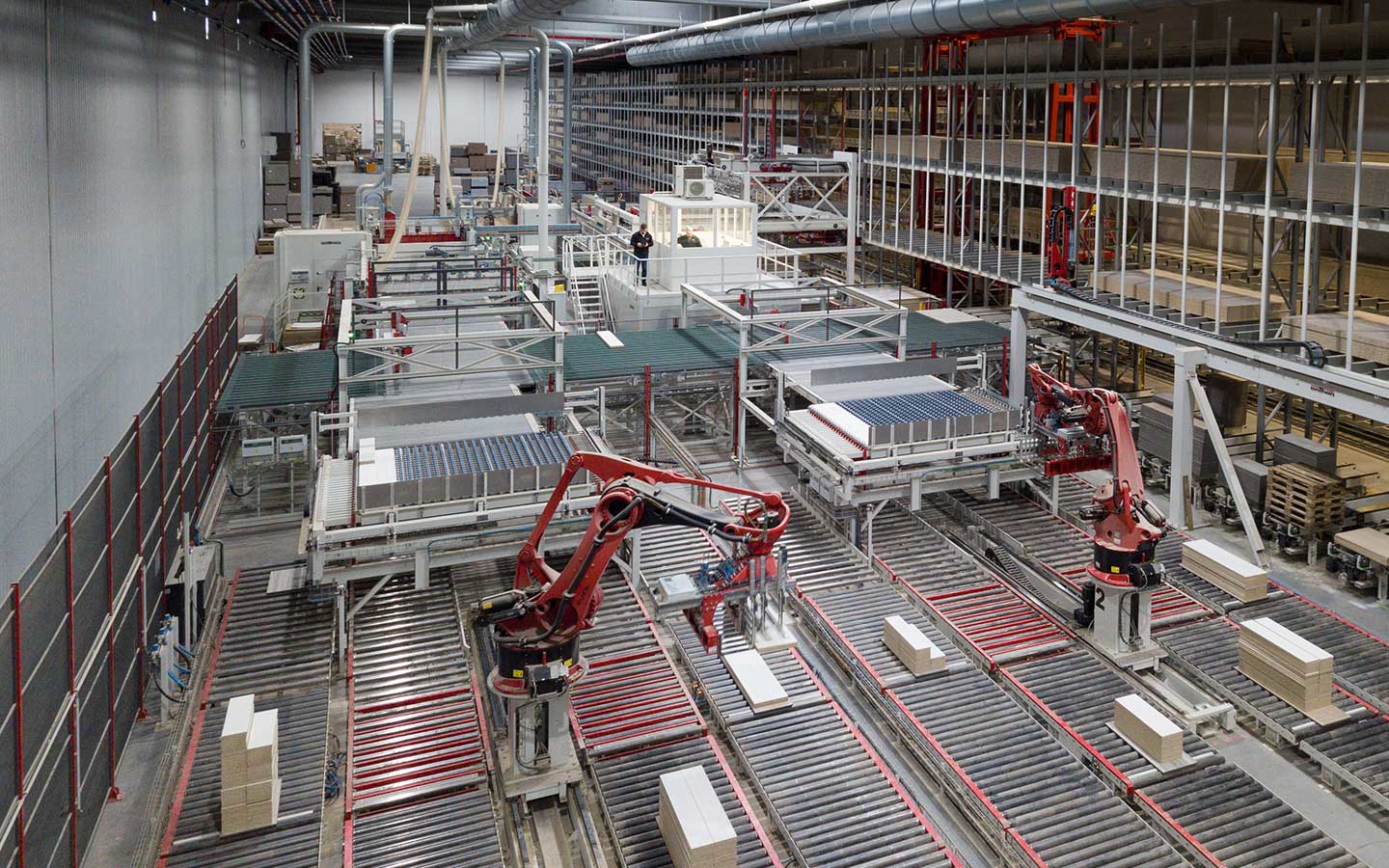

High quality and efficient

Destacking

High performance in dividing requires high performance in destacking. Depending on the desired degree of automation, the material to be destacked and the complexity of the division, Anthon offers various solutions. These range from manual to semi-automatic to fully automatic destacking.

| Type | Spezifications |

|---|---|

| Robot destacking | – Various equipment of the robot tool: from single panel pick-up by means of vacuum to panel package pick-up by means of gripper/ rake tool. – Use in panel cutting; furniture production and panel manufacture |

| Fork destacking | – Pick-up of the panel packs by rakes and stacking on stacking area with the aid of lifting platforms and stripping ruler. – Stacking of multiple parts depending on layer pattern |

| Manual stacking /hand stacking | – Classic manual destacking in combination man – machine – Air table, man and destacking station |

| Stripping-off stacking | – Stacking by pushing on the panel packs – Powerful stacking for large and small formats for insensitive material surfaces |

| Side gripper destacking | – Destacking by lifting the panel packs and destacking with the support of a portal – Powerful destacking for large and small formats for sensitive material surfaces |

| Dropbox | – Single panel and minipack destacking after sanding lines in flow direction – Infeed into /stacking boxes with drop chutes consisting of lifting platforms with alignment units |

| Vacuum destacking | -Single panel destacking by means of a vacuum tool on a moving portal – Layer destacking depending on the size of the single panel or smallest parts as a complete layer |

| Tray destacking | – Pick-up of the panel packs by pusher and tray and stacking on destacking station with the use of lifting platforms and stripping ruler. – Stacking of multiple parts depending on layer pattern |